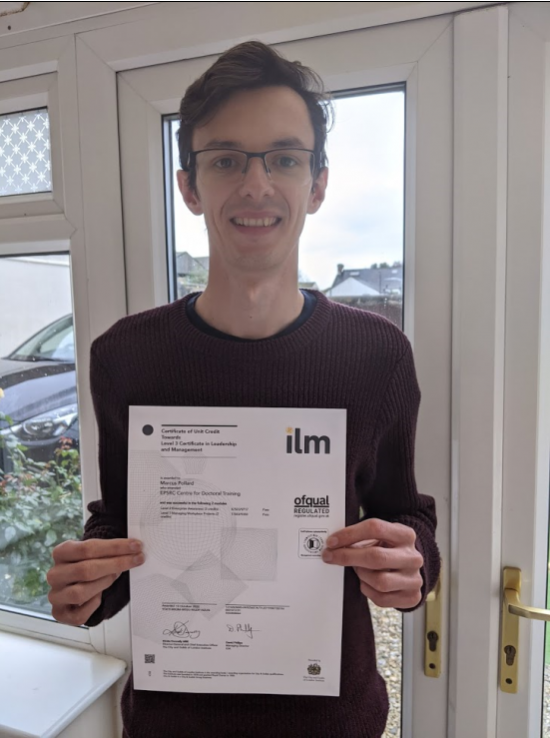

ILM

2 November 2020

A huge congratulations to cohort 3 student, Marcus Pollard on completing his ILM Level 2 Enterprise Awareness and Level 3 Managing Workplace Projects! Way to go Marcus!!

2 November 2020

A huge congratulations to cohort 3 student, Marcus Pollard on completing his ILM Level 2 Enterprise Awareness and Level 3 Managing Workplace Projects! Way to go Marcus!!

30 October 2020

In May, Matthew Hammond presented at the Oil & Gas Focus Group Meeting. The meetings are normally run two to three times a year by TUV-SUD, switching between venues in Norwich and Aberdeen.

Matthew says: "I presented at last years’ meeting in Norwich and was selected to present at this year’s event alongside two other presenters. This year, the meeting was held online for the first time using Microsoft Teams. I presented on a slightly different topic to my PhD project; gas quality measurement challenges in a hydrogen economy. It was quite relaxing presenting from my own home but strange not being able to see the audience. Martin Hanton from TÜV SÜD National Engineering Laboratory also gave a presentation on hydrogen which shows that emphasis is shifting towards renewable energy even in the Oil & Gas sector. Martin talked about hydrogen measurement but from a flow metering perspective, so it was interesting to hear a different side to that topic. At its peak, the number of participants reached around 60 which was a good turnout for the first virtual meeting. The downside of virtual conferences is not being able to talk face to face with the other participants. Overall, everything went smoothly, particularly with the presentation handovers which can sometimes be a technical challenge. I look forward to attending or presenting at future Oil & Gas Focus Group meetings, virtually or in person."

One of our PhD students, Melanie Zimmer, recently had the opportunity to present some of the Intelligent Automation Centre’s and her work at the 17th edition of INDIN2019 held in Helsinki-Espoo, Finland. This year’s conference took place 22nd to 25th July and was hosted by Aalto University. Overall, the conference was well attended and received.

It offered a wide variety of activities: Covering 14 special sessions and three Industry Forum sessions across the three days of the conference, including an additional day on Monday with workshops and hands-on tutorials under the theme of Industrial Applications of Artificial Intelligence. In addition, a Women in Engineering workshop was held on Wednesday afternoon to promote the involvement of women in science, and on Thursday morning attendees had the opportunity to visit ABB in Helsinki or Konecranes in Hyvinkää.

More information about the conference and the Intelligent Automation Centre can be found here:

10 October 2020

On 17th April, the University of Lincoln hosted the 3rd EPSRC UK-Robotics and Autonomous Systems (UK-RAS) Network Conference. Due to the current situation of the Covid-19 outbreak, the conference was held virtually. The conference is in particular aimed at PhD students & early-career robotics researchers and offered current insights into work around the topic of “Robots into the Real World”. Besides invited speakers from the University of Oxford, University of Cambridge, and the University of Edinburgh, researchers got a chance to present their work in oral and poster presentations. Overall, the conference had 64 submissions, with 15 oral and 41 poster presentations accepted – including some of our research students:

Rankin, J, Justham, L, Goh, Y.M., Morley, J: Task Delegation and Architecture for Autonomous Excavators

Foley, B, Ferreira, P, Zimmer, M: Towards Gamification of the Ramp-up Process for Industry 4.0.

Zimmer, M, Al-Yacoub, A, Ferreira, P, Lohse, N: Towards Human-Chatbot Interaction: A Virtual Assistant for the Ramp-up Process.

More information can be found here:

28 September 2020

Our Cohort 5 student, Nelson De-Sousa Campos, attended the Deep Learning Summer School in Poalnd, 2019

Nelson says “Attending the Deep Learning Summer School in Warsaw was an opportunity to stay up to date with what is happening in both industry and academia. The topics that piqued my interest were audio and video processing applications using deep learning. What caught my attention the most was the lecture by a professor from the University of Alabama who was using high-level synthesis for machine learning applications using FPGAs. Furthermore, I used the opportunity to catch up and network on LinkedIn with a research engineer from Fraunhofer in Germany who shares similar interests and have worked in Nvidia at San Francisco.”

26–28 June 2019, at the University of Salford, MediaCityUK Campus, United Kingdom

Our student Melanie Zimmer attended this year’s NLDB2019 conference held at the University of Salford. The conference was first established in 1995 and gives the community interested in applications of Natural Language in the field of Information Systems a platform to come together. The conference covered topics such as information search and topic extraction, classification and sentiment analysis across the various fields of medicine, e-commerce, and social media. In addition to the presentation of the accepted papers, two talks of invited speakers were given: Robert Stevens from the School of Computer Science at the University of Manchester shared his experience in bio-ontologies, and Vijayan Sugumaran from the Department of Decision and Information Sciences at Oakland University talked about detecting different states of emergency events using Web resources to help social groups and first responders handle these events effectively.

The proceedings of the conference can be accessed here:

https://link.springer.com/book/10.1007/978-3-030-23281-8

More information can be found here:

12 September 2020

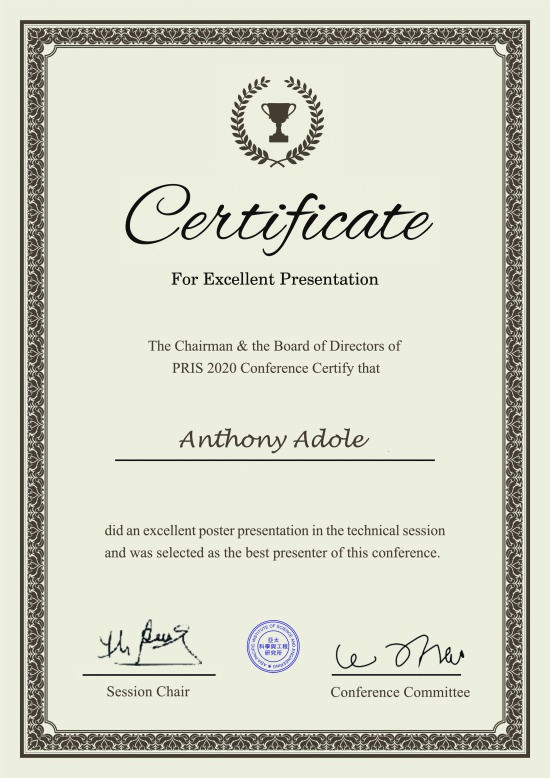

On the 30th July 2020, our Cohort 5 student Tony Adole was able to attend a virtual conference during the lockdown.

This was an international conference on Pattern Recognition and Intelligent systems (PRIS) which was meant to be held in Greece but due to the pandemic, was moved to an online conference.

The conference aims to present the latest research related to pattern recognition, intelligent systems and other related topics. Participants at the online conference were able to exchange ideas by the using oral presentation and poster presentation so they could establish a professional relationship that could enable future collaborations.

At the online conference, attendees were informed that all registered and presented papers would be included into the volume of ACM international conference Proceeding series and it would be submitted to EI Compendex, Thomson Reuters (WoS) and other databases for review and indexing.

For the conference, Tony presented his research on Faster RCNN Inception resnet v2 on Kanji handwriting characters. Due to the nature of his presented research and virtual presentation using a poster medium , his research direction was easily understood which provided him the opportunity to win the best Poster award.

Many Congratulations Tony!

24 June 2020

The Committee of the UK-RAS Network met during the 2020 UK Robotics Week (https://www.ukras.org/robotics-week/) to discuss, amongst other items on collaboration, partnerships and digital infrastructure, the activity ongoing at a National and International level on Robotics and Autonomous Systems this year that is showcased during the Robotics Week. This year the Covid-19 disruption has moved all activities online but this was a good opportunity to learn more about and celebrate the successes of the Network this past year (link to video: https://youtu.be/Uou_RHj8EvA)

The UK-RAS Network committee wished everybody a Happy Robotics Week! (https://twitter.com/UKRobotics/status/1276806236709756930)

The Network brings together the UK’s core academic capabilities in robotics innovation under national coordination and encourages academic and industry collaboration to accelerate the development and adoption of RAS.

The EPSRC UK Robotics and Autonomous Systems (RAS) Network (https://www.ukras.org/) was established in March 2015 with the mission to provide academic leadership in RAS, expand collaboration with industry and integrate and coordinate activities at eight Engineering and Physical Sciences Research Council (EPSRC) funded RAS capital facilities, four Centres of Doctoral Training (CDTs) of which the CDT in Embedded Intelligence is one of them, and with 30 partner universities across the UK.