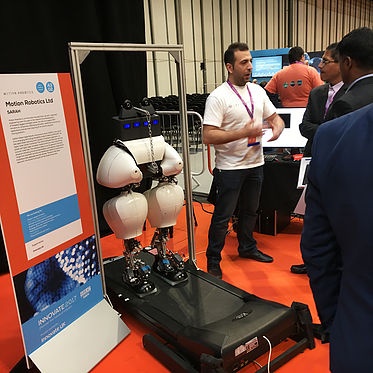

We are a founding member of UK-RAS Network and delighted to have taken part in the first UK-RAS Conference on ‘Robotics and Autonomous Systems’ (RAS 2017). Cohort 2 researcher Rhys Comissiong, Cohort 3 researcher Christos Kouppas and our Centre Manager, Donna Palmer attended the inaugural event.

The conference aimed addressed the synergetic interaction of human and robotic technologies. As robots and agents have begun to enter our everyday lives they begin to do so in an increasingly autonomous way. These increasing levels of interaction will pose serious challenges to the capability of robots to interact with humans in an increasingly autonomous way. The talks were categorised into three general topic areas including 'Assistive robotics' and 'Aerial robotics'. Talks covered a range of application areas from the nuclear industry to health and life sciences.

Oral and poster presentations were given by PhD and early-career researchers from all members of the UK-RAS Network and illustrated the breadth of robotics and AI work taking place across the UK and the fruitful conversations taking place during the breaks demonstrated the importance and relevance of this conference taking place. Prizes were awards for the best presentations and posters, the winners being invited to present at TAROS 2018.

The Image below is of Christos Kouppas presenting his work.